What Industrial Systems Teach Us When We Slow Down: Reflections Around a Rexroth Dealer in Bhubaneswar

Most industrial failures are not sudden. They are quiet. They arrive slowly, shaped by habits, assumptions, and overlooked details. Machines rarely stop without warning; they speak long before they fail. The challenge is whether anyone is listening.

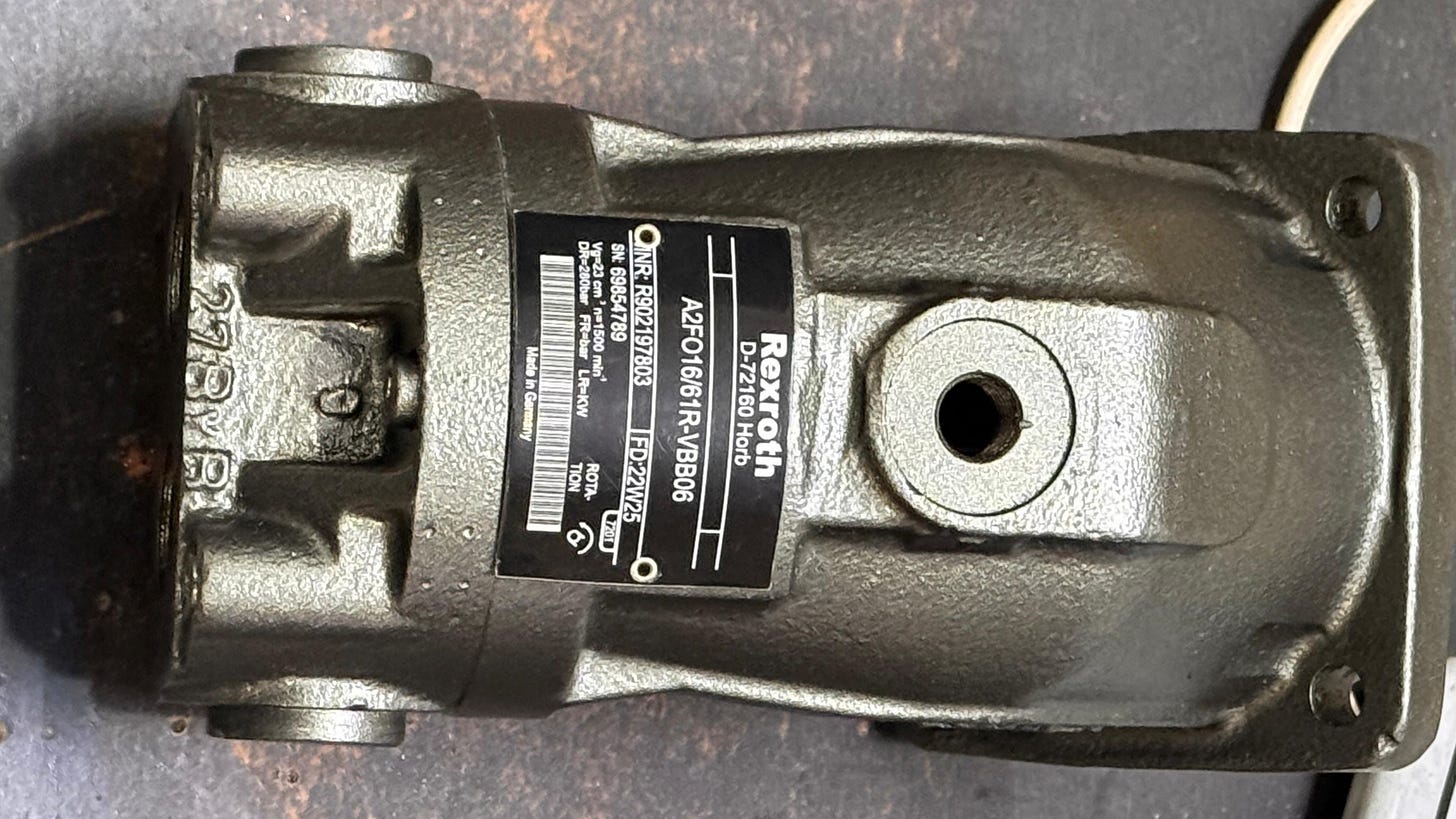

Hydraulic and motion systems are especially communicative. Pressure changes, response delays, thermal shifts—each is a form of language. In regions where industrial activity continues to evolve, such as Bhubaneswar, the idea of a rexroth dealer in bhubaneswar becomes less about location and more about how technical understanding finds a place to live.

Industry Is Built on Attention, Not Just Infrastructure

Factories are filled with powerful machines, yet reliability depends less on strength and more on sensitivity. Systems that are closely observed tend to behave predictably. Systems that are ignored slowly drift out of balance.

Understanding machinery means noticing patterns:

How a system sounds under load

How it responds during startup

How movement feels after long cycles

These details often matter more than specifications.

Fluid Power Is Quietly Adaptive

Hydraulics do not demand attention. They adjust silently, redistributing energy as conditions change. This adaptability is what makes them valuable—and also what makes neglect dangerous.

When fluid systems are respected, they offer:

Gentle force transitions

Reduced mechanical shock

Tolerance for variation

Longevity through balance

When they are pushed without awareness, stress accumulates invisibly.

Motion Control and the Discipline of Restraint

There is an industrial obsession with speed. Faster cycles. Quicker movement. Higher output. Yet motion control teaches a different lesson: stability comes from restraint.

Controlled movement protects alignment.

Measured acceleration reduces fatigue.

Predictable positioning builds trust.

In many ways, motion control reflects good decision-making—acting only when necessary.

Why Local Understanding Still Matters

Global engineering knowledge is abundant, but industry does not operate in global conditions—it operates locally. Climate, workload patterns, and operating culture shape how systems behave.

The relevance of a rexroth dealer in bhubaneswar lies in this local translation of technical understanding. It represents how abstract design principles meet real-world environments.

The Cost of Ignoring Small Signals

A slight temperature rise becomes “normal.”

A delay in response becomes “expected.”

A vibration becomes “part of the process.”

These adjustments feel harmless until they accumulate. Most breakdowns are not mechanical failures; they are failures of attention.

Observation as a Form of Maintenance

There is a quiet skill in watching systems without rushing to intervene.

Noticing pressure trends.

Sensing changes in rhythm.

Comparing today’s behavior with yesterday’s.

Organizations that value observation often avoid urgency—not because problems don’t arise, but because they are recognized early.

System Drift Is a Human Problem

Machines rarely forget their limits. People do.

When output pressure overrides patience, systems drift. When efficiency replaces understanding, instability grows. Drift is not a technical flaw; it is a behavioral one.

A Different Measure of Reliability

True reliability is calm operation over time.

Few surprises.

Few emergencies.

Few rushed decisions.

This kind of reliability is built through awareness, not acceleration.

Closing Thought

The idea of a rexroth dealer in bhubaneswar fits into a larger narrative about how industry learns. When organizations value interpretation over assumption and observation over reaction, machines respond with steadiness.

Industrial wisdom is not loud.

It is quiet, patient, and attentive.